Professional rotary hammers - an overview of the best models and recommendations for choosing

In this article we will tell you what to look for in order to purchase the best professional-grade puncher, as well as review the best models of punchers designed for permanent work.

How to choose a professional hammer drill

Professional models of rotary hammers differ from household models in power, endurance and a long period of continuous operation. To choose the best option for such a power tool, first of all, you need to pay attention to the following characteristics:

- Type of percussion mechanism.

- Power and energy of impact.

- Type of drill attachment.

- Anti-vibration protection.

- Spindle speed

- Brush reverse.

- Power or cordless tools.

A professional class cannot be called a cheap tool, so the master must clearly understand what qualities an optimal model should have.

Type of percussion mechanism

In punchers, one of two types of impact mechanism can be used: pneumatic or electromechanical.

Pneumatic hammer

The principle of its operation is that the piston of the drive mechanism compresses the air cushion. The second, free piston, is surrounded by air on both sides. He moves forward to the striker, transferring the created effort to him.

Then the piston of the drive mechanism moves back. At this time, the free piston pushes away from the hammer, which moves back. The compression of the air bag on the other side of the free piston increases, causing the piston of the drive mechanism to stop.

Under the influence of high pressure, the free piston flies back to the striker with increased speed. The impact is transmitted to the tool during the operation of the tool.

Watch the video how the pneumatic impact mechanism works:

Important! When choosing a hammer drill for professional use, it is worth giving preference to the pneumatic type impact mechanism.

Electromechanical Impact Mechanism

The electromechanical system that creates the shock force is often equipped with light models. In such systems, the lever spring is driven by an eccentric. It moves the percussion device back and forth. Through a special drummer, the force is transmitted to the snap. Recoil is absorbed by the spring, amplified by moving the mechanism forward. This system is less hardy, it is not used for long, high loads on the tool.

Watch the video on the principle of the impact mechanism of the electromechanical type:

Power and impact energy

Professional models have impact energy from 7 to 27 J. The higher this indicator, the more productive and durable the tool. The power of a professional type tool is from 1 kW.

Such equipment has a wide range of functions:

- drilling holes, including diameter over 100 mm;

- natural stone drilling;

- concrete spalling when widening openings;

- creating a gate for laying communications.

Drill Mount Type

To fix the drill in the perforators, a quick-detachable fastening system of the SDS type is used. The most common is the SDS Plus drill mounting system, but it is not used on professional rotary hammers. For professional models, the mount has been improved. This type of power tool has a SDS max mount. Designed for use in high shock mode.

Cross section of SDS Plus and SDS Max shanks:

SDS Plus.

SDS Max.

The diameter of the SDS max tool shank is 18 mm, which makes it more reliable. The design of the cartridge has a number of features. The shank in it is fixed using 5 grooves. Often punchers with SDS max work in 2 modes: drilling with a punch or only a punch. Therefore, it is impossible to use a perforator of the presented class for simple drilling and creating precise holes.

SDS-max tool shank.

Anti-vibration protection

Professional-grade rotary hammers are equipped with active anti-vibration protection. You can work with such a power tool all day long, taking only small breaks.

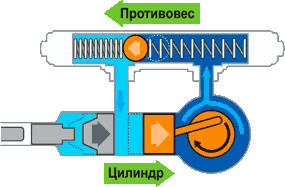

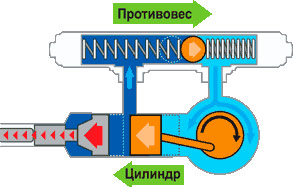

The basis of the anti-vibration system is a dynamic counterweight, which is located inside the case of such devices. The mechanism absorbs vibrations that are transmitted to the hands of the master. This significantly reduces the likelihood of developing a professional disease called tunnel syndrome.

Anti-vibration punch system.

Dynamic counterweight device:

In household models, the simplest passive anti-vibration protection is provided. Therefore, the use of such a technique in professional activities is undesirable. Over time, health problems can occur.

Spindle Speed and Impact Frequency

The rotation speed of the tooling depends on the spindle speed. This indicator is inversely proportional to power. Rotation is necessary for the removal of sludge generated during drilling from the hole.

If the master often uses a puncher for drilling holes, it is better to give preference to a model with an indicator of up to 2000 rpm. For drilling, a high rotation speed is not needed and a hammer drill with a spindle speed of up to 1000 rpm is suitable.

Impact frequency is one of the most important indicators of a hammer drill. The higher this value, the faster drilling will occur.

Electronic and brush reverse

The reverse function is provided in many modern models of professional-grade perforators. In this mode, the drill moves in the opposite direction, which makes it easy to extract it from any material.

The following reverse types are used in rotary hammers:

- Electronic. The position of the brushes with this type of reverse does not change. The direction of the torque is changed electronically. Power drops because of this, and the brushes wear out faster. Electronic reverse is used on low-cost models of domestic airborne guns.

- Brush. This is a more advanced reverse system. Switching is done by turning the brushes, which avoids a drop in power. The mechanism is more complex, which increases the cost of equipment. But for professional use it is more advisable to choose a brush reverse.

Power or cordless tools

Professional builders, repairmen have to work in different conditions. If the site is small, it has a stationary power supply system, it is better to give preference to network models.

Cordless rotary hammers are used in facilities where there is no access to the mains. Similar models are used when performing work at heights, in a limited space. Also, a cordless hammer drill is more convenient to use if you need to drill holes along a long fence or building facade.

The performance of a professional power tool with a battery is not inferior to some network models. The only drawback of the battery technology is the limited operating time. Therefore, it is better to purchase models with two batteries or purchase another battery additionally. While one battery is being recharged, you can continue to work.

The puncher with the battery is chosen by the installers of ventilation, windows, air conditioners, other workers traveling to different facilities.

The best professional rotary hammers

Next, we consider the most successful models of professional-grade perforators. This is a hardy, durable, multi-functional technique. Each model has pros and cons, which is important to consider when choosing the best option.This rating of professional-grade rock drills was based on user reviews and the technical parameters of this power tool.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

|  |  |  |  | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bosch GBH 5-40 DCE | DeWalt D 25601 K | Makita HR 4501 C | AEG PN 11 E | Makita HR 4511 C | |||||||

| Max impact force, J | 8,8 | 8 | 13 | 27 | 13 | ||||||

| Power, W | 1150 | 1250 | 1350 | 1700 | 1350 | ||||||

| Spindle speed, rpm | 170 - 340 | 210 - 415 | 130 - 280 | 125 - 250 | 130 - 280 | ||||||

| Impact rate, bpm | 1500 - 3050 | 1430 - 2840 | 1250 - 2750 | 975 - 1950 | 1250 - 2750 | ||||||

| Max diameter of drilling with a drill (concrete), mm | 55 | 45 | 45 | 50 | 45 | ||||||

| Max diameter of drilling with a crown (concrete), mm | 90 | 100 | 125 | 150 | 125 | ||||||

| Weight, kg | 6,8 | 6,8 | 7,8 | 11,8 | 8,5 | ||||||

Bosch GBH 5-40 DCE

Professional-grade network punch with 1150W motor. The spindle speed is 170-340 rpm./min., And the impact frequency is 1500-3050 beats / min. The impact force of the tool reaches 8.8 J. Using the Bosch GBH 5-40 DCE puncher, you can drill holes in concrete with a diameter of up to 55 mm with a drill, and up to 90 mm with a crown.

+ Pros of Bosch GBH 5-40 DCE

- A fairly powerful tool, which at the same time weighs relatively little.

- Holes can be created quickly even in very hard materials. On hard concrete, you can work an hour without turning off the punch. With increased load, the number of revolutions does not change.

- High-quality German assembly, which ensures the durability, endurance of the power tool.

- A large power reserve extends the functionality of the hammer.

- A high-quality anti-vibration system reduces the pressure on the hands.

- The engine starts smoothly, it is possible to adjust the speed.

- When jamming or overload protection is triggered.

- In a convenient case not only a power tool is placed, but also all the necessary drills, crowns.

- Cons Bosch GBH 5-40 DCE

- The tool is very hot. In winter, the cooling process does not take much time, but in summer you have to take breaks up to half an hour.

- There is no reverse, which complicates the extraction of the drill.

- After many years of operation, the number of revolutions may vary slightly under load.

- No drilling mode.

Conclusion. In general, this is a workhorse that copes with the tasks assigned to it. It is used in the process of erection, repair of various objects (houses, garages, fences, etc.).

DeWalt D 25601 K

The power tool has a power of 1250 watts and is suitable for making holes with a drill diameter of up to 45 mm and crowns up to 100 mm. The puncher works in a mode of chiselling and drilling with blow.

+ Pros of DeWalt D 25601 K

- A powerful tool weighs relatively little, which allows you to work with it for a long time, without getting tired. In this case, the punch is not heated.

- Ergonomic handle, vibration damping system provide comfort of work. Hands get much less tired after an 8-hour day.

- The presence of a safety clutch allows you to instantly stop the work of the hammer. This allows you to avoid personal injury, equipment damage.

- The hammer drill is designed to work even with very durable materials that have reinforcement.

- The design has service indicators. The color of the light bulb indicates the type of failure.

- When creating openings, the brick does not crack. It is possible to create a clear rectangle, which simplifies the subsequent work.

- A small case allows you to carry around the tool and the necessary accessories.

- Cons DeWalt D 25601 K

- Possible release of grease from the barrel during prolonged use.

- The protective mechanism when jammed sometimes works with a little delay.

- The length of the cord in some cases is not enough. But this drawback does not interfere with most of the standard construction and installation operations.

Conclusion. The tool is suitable for construction, plumbing, electrical work. But to create holes at a height it is better to give preference to other models.

Makita HR 4501 C

A sufficiently powerful professional model with a 1350 W electric motor, working in the drilling mode with impact, chiselling. The maximum size of the holes created by the drill is 45 mm, and the crown is 125 mm.

+ Pros of Makita HR 4501 C

- A powerful tool easily works with any modern building materials. The impact force is very large (13 J).

- The assembly of perforators of this model is carried out in Japan. Therefore, the tool is high-quality, durable. Even with a significant, prolonged load, the elements of the system do not fail.

- The kit comes with a regular and D-shaped handle, which increases the comfort of operation of the power tool.

- Start-up is smooth, a convenient system for switching speeds is provided.

- There is an indicator that indicates the need to replace carbon brushes.

- Cons Makita HR 4501 C

- The mode switch is quite tight. In some cases, manually adjusting it is almost impossible. I have to use pliers.

- The large weight of the punch (7.8 kg) does not allow working with it for a long time.

- There is no reverse mode, which also complicates the work.

Conclusion. High-quality tool for professional installation of electrical, plumbing communications. It is used in the construction of various objects, coping with a wide range of tasks, including the creation of niches in the walls and more. It takes time to get used to the heavy equipment.

AEG PN 11 E

The powerful unit with a 1700 W engine and impact force of 27 J has two handles in the kit for choosing the optimal grip. The maximum openings created on brown concrete have a diameter of up to 50 mm and a crown of 150 mm.

+ Pros AEG PN 11 E

- The manufacturer provides for the presence of the AVS system, which reduces 50% of the vibrations. This reduces the load on the hands of the master.

- A powerful technique that can not only create holes, but also make openings in very hard materials.

- During operation, the tool does not heat up. Even with prolonged use at high loads, the case remains slightly warm.

- When jammed, the stop mechanism works quickly.

- Long term of operation. Even when working on wear, the tool works much longer than the warranty period.

- Cons AEG PN 11 E

- It’s hard to work in horizontal position.

- When used in jackhammer mode, the handle may gradually unscrew.

- The punch is too heavy (11.8 kg). Some masters argue that without a tripod can not do.

Conclusion. This is a powerful power tool that is used when carrying out heavy work associated with crushing, drilling. It is mainly used in an upright position.

Makita HR 4511 C

The 1350 W network punch works in the drilling and chiselling mode. The maximum impact force is 13 J. A puncher drills holes in a concrete with a diameter of up to 45 mm with a drill, and with a crown up to 125 mm.

+ Pros of Makita HR 4511 C

- It is convenient to work with a puncher. The model is well balanced, has an ergonomic body, allows you to work comfortably with long equipment.

- Start-up is smooth.

- There is an AVT system in the rear handle that reduces vibration. This makes the work tireless.

- Frequency and impact force are easily adjustable. At the same time, maximum power is enough to crush durable materials.

- There is a malfunction indicator of the power cord and switch.

- In addition to the case, the grease is supplied in a convenient tube, 2 handles.

- The tool heats up slightly under load.

- The tool is assembled in the UK, so its quality is high.

- Cons Makita HR 4511 C

- The mode switch is tight, you have to use pliers.

- A large, heavy tool that makes work difficult.

- The weight of the case is also large. Carrying it with you is inconvenient.

- Lack of reverse, which complicates the process of extracting the drill from the material.

Conclusion. This model is designed for predominantly vertical drilling and drilling. You can perform short-term work in the horizontal plane. The puncher is used in professional installation work, large-scale construction.